Shandong Lutong Heavy Industry Equipment Co., Ltd. Introduces New Generation of Telescopic Handler Axles: Innovative Technologies for the Global Special Equipment Market

[With Ki, Shanghun]

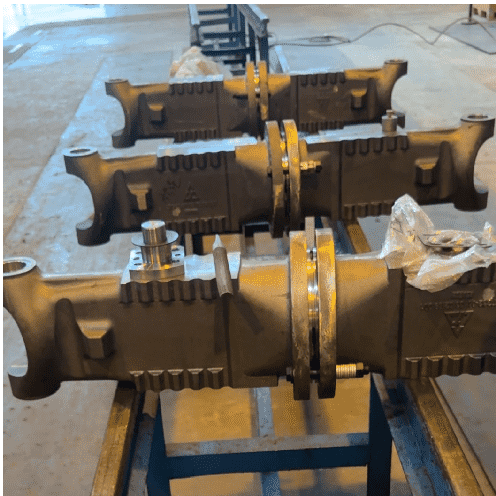

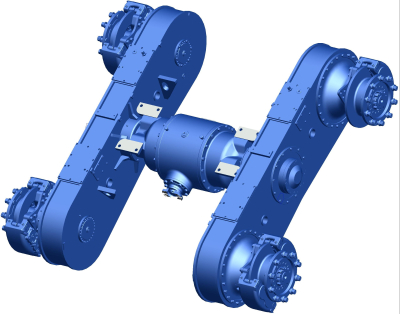

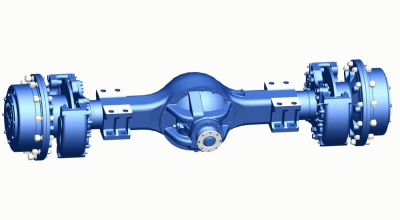

The leading manufacturer of the leading bridges, Shandun Lutun, officially announced that the special leading bridge for telescopic loaders developed by him switched to the stage of the workshop assembly, which marked the company's breakthrough in the field of transmissions for off -road equipment. Thanks to the integrated wet brake system "Motion-Staff", a two-stage intellectual reduction system and modular architecture, this product can be a revolutionary solution for the special equipment market.

Why will this leading bridge become a new world standard?

1. The intellectual drive and braking system, redesign security and efficiency

Two -stage gearbox + adjustment of the gear ratio: flexible setting for various models, providing high torque at low speeds or high performance adapted to various working conditions around the world.

Integrated wet brake system: The use of high-quality brake pads increases the braking torque by 35%, resistant to high temperatures, dirt and other difficult conditions, greatly reducing the risk of brake failure.

2.Passability in extreme conditions for difficult working environments

Dual mode limited slip differential with positive locking: intelligently distributes power between wheels, easily copes with mud, steep slopes and uneven terrain, positive locking ensures 100% power transmission.

Low center of gravity, one-piece oscillating frame design: optimizes vehicle stability, reduces the risk of rollover, while simplifying the installation process for manufacturers and reducing frame construction costs.

3.Modular design for convenient global adaptation

Standardized interfaces support quick replacement, compatible with global telescopic handler models, improve installation efficiency by 60%, greatly shortening the delivery time for customers.

On the production line for telehandler drive axles, every step is based on the "zero defect" principle

From component processing to axle assembly, the quality control department carries out continuous supervision, ensuring that every drive axle produced meets global reliability standards.

Rigorous Assembly Process: 7 Key Checkpoints

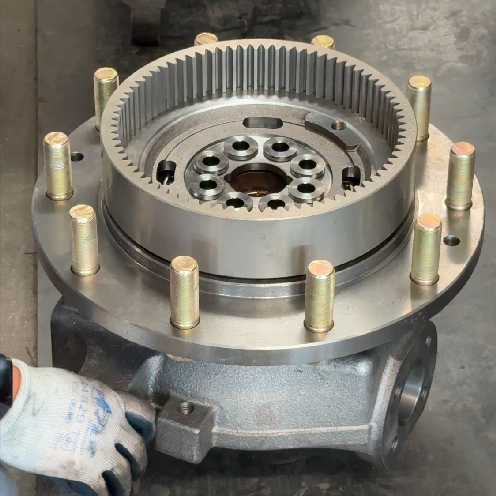

Preliminary inspection of parts: 100% of incoming parts are checked by coordinate measuring machine, critical dimension error ≤ 0.02 mm

Spectral analysis of key components such as gears and bearings for material testing

Cleanliness control: all parts undergo ultrasonic cleaning and compressed air blowing before assembly

Gear meshing accuracy adjustment: continuous monitoring of the contact patch during assembly

Engagement noise level ≤ 78 dB (industry standard 85 dB)

Brake system calibration: wet brakes undergo 200 running-in cycles on a special stand

Dynamic Bridge Testing: 72-hour rig testing simulating real operating conditions including:

✓ Full power impact tests

✓ Testing braking performance at high temperatures

✓ 2000 differential lock test cycles

Shandong Lutong adheres to the quality policy of "three no's":

❌ Do not accept non-conforming parts

❌ Do not install components with an undefined state

❌ Do not release products that do not meet standards

Why Choose Shandong Lutong Quality Assurance?

✅ Longer service life: rated life of 10,000 hours, which is 1.5 times higher than the industry average

✅ Lower maintenance costs: modular design reduces maintenance time by 50%

✅ Better adaptation to environmental conditions: operating range from -40°C to 85°C

✅ Fast service response: Global commitment to 48-hour technical support

Shandong Lutong: Creating a Benchmark for Chinese Manufacturing with a Global Vision

Shandong Lutong has been engaged in the field of drive systems for special equipment for more than 32 years, possessing the production capacity to produce 50,000 drive axles of various models, 20,000 gear groups and torque converters per year. The company exports reliable and high-performance drive axles for powerful tractors to Russia, having received full recognition from the Russian market.

The company has implemented the ERP management system, complies with the ISO9001-2015 quality management system standard, ensuring high-quality operation of the enterprise. We have advanced testing equipment, including coordinate measuring machines (hexagonal) and MDS metallographic microscope, which guarantees the quality of products.

We strive to meet individual customer needs through quality products and excellent after-sales service.