Innovations in forestry equipment: technological evolution from logging and material collection to sustainable forest management

What is logging equipment?

Forestry equipment is the main system of tools for conducting forestry, harvesting and processing wood, covering the entire production chain - from manual chain saws to fully automatic logging machines. With the transition of the world forestry to sustainable development, such equipment provides a balance between production efficiency and protecting the environment through technological innovation - according to the latest study of the market - the market of the market (Researchandmarkets, 2025), the volume of the global forestry technology market is expected to increase from 111.33 billion US dollars in 2024 to 14.51 billion US dollars in 2030, the aggregate annual growth rate of the company is 4%, and its driving force is an acute need for effective and environmentally friendly equipment.

1. The impact of industrial changes in forestry engineering

The traditional logging industry once relied on high-intensity human labor, but modern logging machinery has completely changed the logic of production.:

Increased efficiency: One harvester can perform logging, branch removal and pole trimming simultaneously, replacing the work of dozens of people.

Environmentally friendly: selective logging technology protects the ecology of surrounding forests and reduces soil erosion and destruction of wildlife habitat.

Cost optimization: Mechanization of the entire process reduces the overall cost of timber by more than 30% (industry research data), while ensuring stability in the timber supply chain.

2. Technological breakthroughs in the core equipment supply chain

Currently, a clear division of labor system has developed in the forestry equipment market:

1. Innovation to complete logging

As a technology integrator, the Harvester is equipped with an intelligent measuring system to achieve precise timber cutting in diameter and length, and a high-torque drive axle system to ensure stable operation in difficult forest terrain. Traditional tools such as chain saws and axes are still indispensable for careful logging.

2. Updating the consolidation channel

The skidder transports logs to the distribution point using steel cables or hydraulic grabs, and its reinforced drive axle must withstand increased traction; the forwarder handles short-distance transport tasks, and the multi-axle drive and differential lock function have become key technologies for working on muddy slopes.

3. The emergence of special equipment

Considering the needs of sustainable forestry, multifunctional equipment shines brightly:

The wood chipper (mulcher) transforms vegetation on site and enriches the soil with organic matter

Chipar produces standardized wood chips to support biomass energy

The Stump Grinder features a high offset drive axle for complete surface cleaning on difficult terrain.

3. Industry pain points create incentives for technological innovation

In a global market dominated by North America (38% share), the equipment faces three major challenges:

Extreme working conditions: Unstructured terrain such as mountains and swamps increases equipment failure rates by 40%.

Maintenance Costs: A single outage of traditional equipment can cost up to $5,000 per day (industry report).

Individual requirements: various scenarios of operation in forests require various equipment configuration.

4. Modular leading bridge: a reliable power core

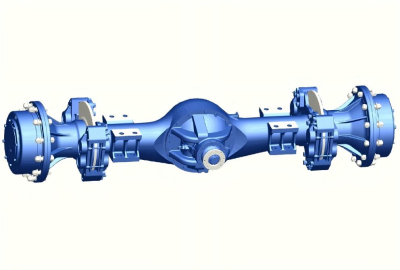

Given the total annual growth rate of the global logging market by 4%, reliable, intellectual and easy to maintain, the drive equipment was a key breakthrough in the modernization of equipment. Considering the harsh operating conditions of logging machines in an impassable forest area, the modular system of leading bridges, developed by our company, allowed to significantly increase the performance due Innovative design.

The product has a modular design that allows customers to flexibly configure the type of brake system, differential type and connection size in accordance with real working conditions. You can quickly adapt all the components, starting from northern antifreeze for extreme temperatures to high -temperature cooling components for tropics. This is a structurally optimized maintenance system significantly reduces the cost of the entire life cycle - the modular design makes dismantling and maintenance more convenient, reduces 70% downtime compared to traditional maintenance solutions bridges and reduces the costs of one -time maintenance by 65%, radically solving the problem of loss of production capacities caused by refusals in forestry. machinery.

Given the features of the relief of forests, the product was specially improved: the design with a great displacement effectively prevents collision with fallen wood and stones and improves cross -country ability by 20% compared to conventional products; It is equipped with a differential blocking that ensures automatic rotation of sliding wheels. It is blocked when working on mountain slopes to ensure the effective transmission of electricity; The design is reinforced to ensure the stability and safety of equipment on uneven ground. This is the design concept, which combines the flexibility of tuning, the convenience of maintenance and adaptability to the terrain, determines in a new way the quality of the drive systems of logging equipment.

5. Technological future of stable forestry

With the acceleration of electrification trends (such as John Deere electric combines) and intellectualization (autonomous vehicles for garbage collection), the drive system evolves towards the “mechatronics.” Nash the modular platform reserved an electric drive to support a hybrid /purely electrical transformation, helping customers realize market opportunities in the amount of 114 billion bills US dollars in 2030.