Shandong Lutong Unveils Full Range of Loader Drive Axles

In the field of construction, agricultural and mining equipment, the leading bridge, as a key element of transmission, directly affects the efficiency of equipment. Among these industries, loaders are an indispensable technique and depending on the chassis and working equipment are divided into three main types: wheel loaders, caterpillar loaders and loaders with a reverse shovel. Like a professional manufacturer of leading bridges, we deeply understand the various requirements of the loaders for the transmission and therefore offer the full line of bridges of the loader.

Three main categories accurately determine the rules of the game and adapt to the working characteristics of various loaders

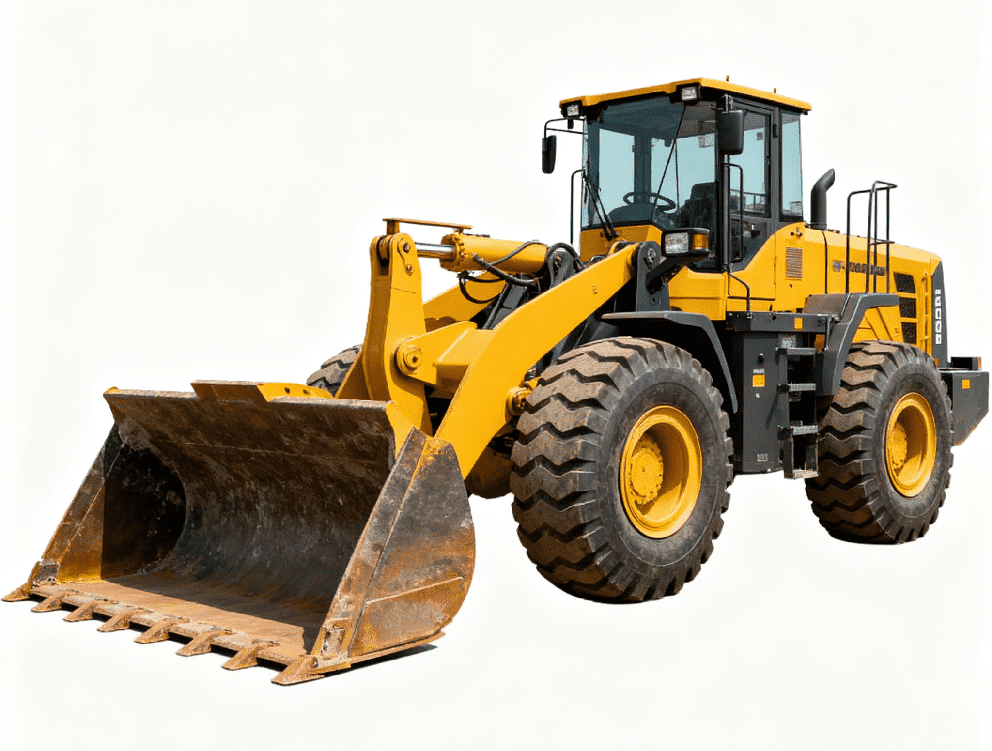

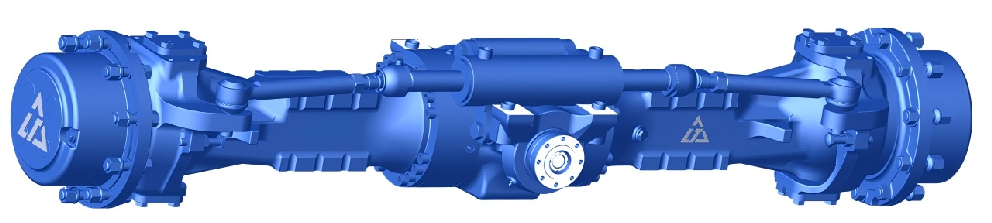

Wheel loader

The wheel loader is equipped with a tire mechanism, which is characterized by a high speed of movement and flexible maneuverability. It is especially suitable for cases when construction sites must be often moved. It implements the design concept "Unified working device + heavy chassis". The front part is equipped with a large-border of large capacity, and lift and unloading are carried out using a hydraulic arrow. The design of the entire machine is based on a linear layout, which emphasizes the stability of the work. Kapoleous loaders are widely used in loading and unloading at construction sites, loading and unloading containers in ports, stacking agricultural products and building urban infrastructure.

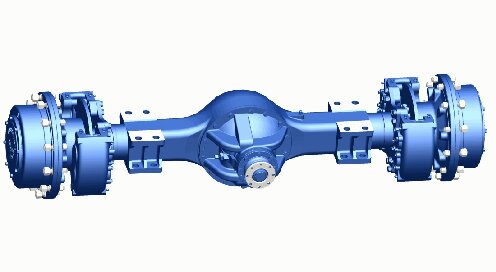

Wheel loaders became the best choice, especially for large-scale loading and unloading work, such as large mines and building materials, due to their high loading efficiency and the possibility of transportation over long distances. Therefore, the leading bridge of wheel loaders should be stable at high speeds, adaptability to difficult operating conditions and unpretentiousness in maintenance. Many years of experience in the production of leading bridges, the level of leading bridges of the wheel loaders of Shandong Lutong, much exceeds the industry level. As an excellent product, the leading bridge of the 5-ton loader, the trust of many equipment manufacturers gained the trust of many equipment with ten leading domestic manufacturers of equipment in the industry, such as Sany, Shantui, Liugong, Lovo, etc. At the same time, our leading bridges for loaders are also exported to Russia, and we also established long-term employment With many large manufacturers of equipment, such as PTZ and UMG. The level of accident rate of exported products is zero, and high -quality leading bridges have passed industry certification.

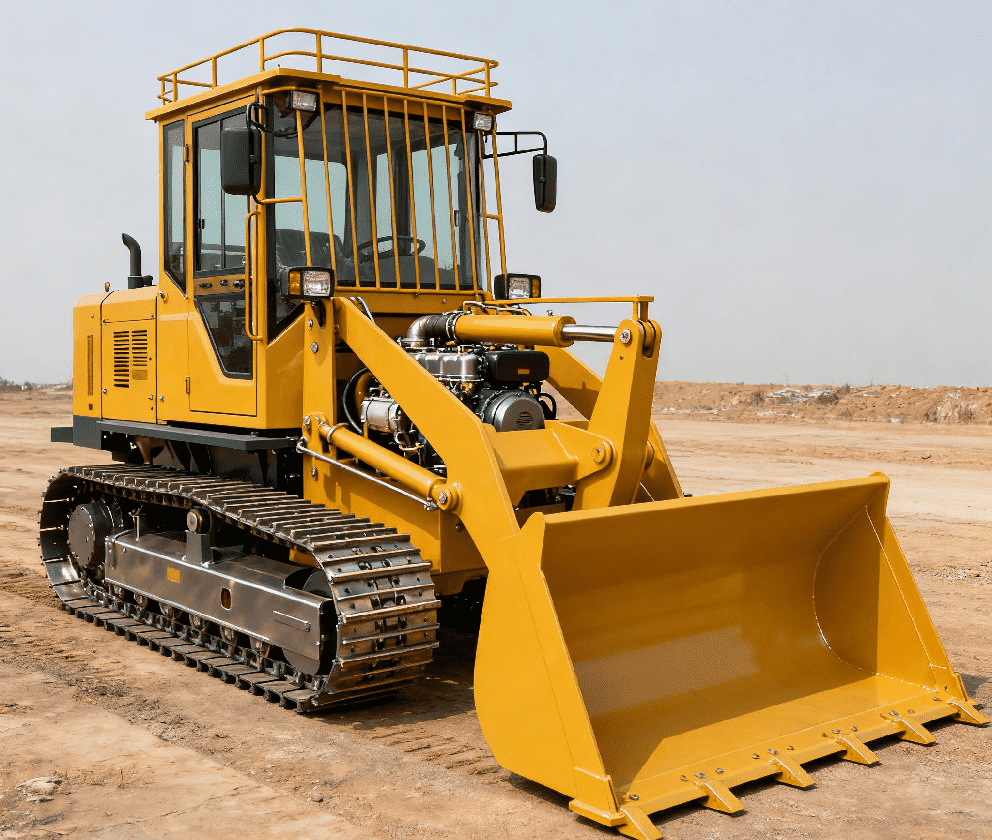

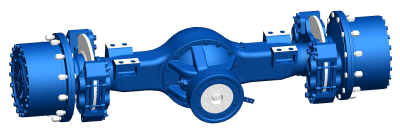

Crawler loader

Caterpillar loaders are construction equipment and equipment on a caterpillar. Their main functions are raking and transporting bulk materials, such as sand and gravel, soil and ore. They can also help in cleaning the territory and bulldozer. They are widely used in the mining industry, the construction of infrastructure, the transformation of agricultural land, forestry operations and other scenarios. The husser engine was designed with a large grounding area and small specific pressure on grounding. It can resist the dirty, soft or crossed soil, it is not easy to get stuck in it, and it is suitable for difficult working conditions, which are difficult to enter wheeled equipment. The equipment, as a rule, consists of a front bucket, a mechanism for moving on a caterpillar, system of power and control systems. A bucket can adjust the angle of inclination and height using a hydraulic system to flexibly comply with the needs of various operations. This is the usual equipment for loading and unloading and basic operations at complex facilities, but its speed is lower than that of wheel loaders, and it is mainly used in the wild or in difficult working conditions.

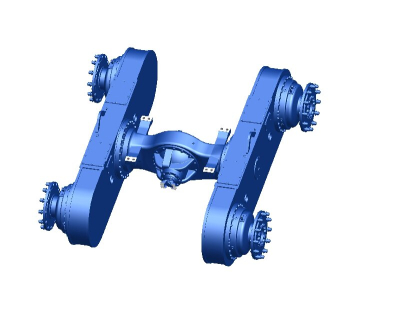

Backhoe loader

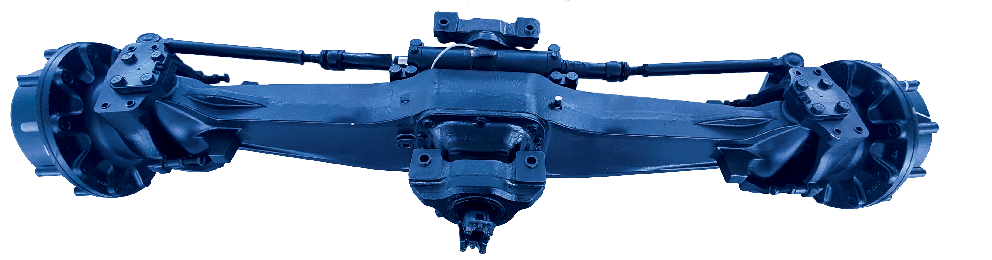

Excavators-loaders are a class of construction equipment and equipment with excavator buckets as the main working device. The main function lies in digging soil, sand, gravel, silt and other materials underground or working plane, and can also help in loading and unloading, digging pits, trimming the foundation for the foundation and other tasks. This is the usual equipment for small and medium surgical work. Compared to frontal excavators, excavators, excavators do not need to rely on high platforms for work, and they can directly dig the foundation and trenches for pipes underground, and the bucket has a large angle of rotation, which provides more thorough unloading; Compared to conventional wheel loaders, it takes into account the functions of soil excavation and loading and unloading without the need to interact with excavators, which reduces the cost of equipment; Compared to caterpillar excavators, it has a higher speed of movement, high switching efficiency, and it can also switch buckets, broken hammers and other accessories using quick -change devices, which simplifies operation. The script is more flexible.

The new leading bridge of the excavator-carrier developed by our company was specially created for work in a reverse shovel with "frequent starts and stops, significant load fluctuations, the need to combine digging and movement functions": the use of a high-strength alloy building increases the lifting capacity by conventional bridges, which allows you to withstand shock loads in digging; optimized planetary transmission provides efficiency over 96%, reducing power loss and adapting to low -speed digging modes with a high torque and rapid movement; the integrated system of protection against leaks increases the service life by 20% in the conditions of dirt and dust on construction sites. Power transmission, helping excavators-loaders increase the efficiency of work in areas such as small and medium excavation, municipal services and repair operations.

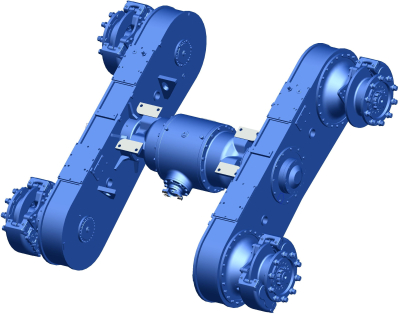

Customized R&D + strict quality control to ensure the high competitiveness of the core product

As a professional manufacturer, who has been actively working in the field of leading bridges for many years, Shandong Lutong has always paid attention to “adaptation to operating conditions” as the basis of research and development. The release of the full assortment of the leading bridges of loaders is deep research conducted by the company based on work on work in various industries - by collecting actual working parameters of almost a thousand loaders A model of the work of leading bridges in various scenarios was developed, and the technology was improved with the “universal” on an “individual approach”.

Within the framework of the product control system, SHANDONG LUTONG has introduced the testing system for the entire process: from checking the mechanical properties of raw materials entering the plant to the test for imitation of dynamic loads in the production process and 100-hour continuous testing during full load before the release of the finished product from the plant, to ensure the compliance of each leading axis with the conductor of the industry standards Reliability. At present, the products of this series have passed certification on the ISO 9001 quality management system and a number of industry tests.

Provide effective work in many industries and begin a new stage in the development of transmitting technologies.

“Types of loaders are different, and the requirements for the performance of the leading bridge are very different. Nash the goal is to make each loader correspond to the“ individual ”transmission scheme.” To date, the entire assortment of the leading bridges of loaders has been introduced at a number of domestic mining enterprises, municipal machine -building companies and cooperatives for agricultural equipment. Shandong Lutong will continue to engage in the research and development of the main technologies of leading bridges and plans to release a series of electric leading bridges for the new Energy loaders. At the same time, the company will deepen cooperation with manufacturers of construction and agricultural equipment to provide complex decisions in the field of transmission, starting with design, from production to after -sales service, which increases operational value for users around the world.