LU TONG Successfully Delivered the First Batch of Telescopic Handler Axle

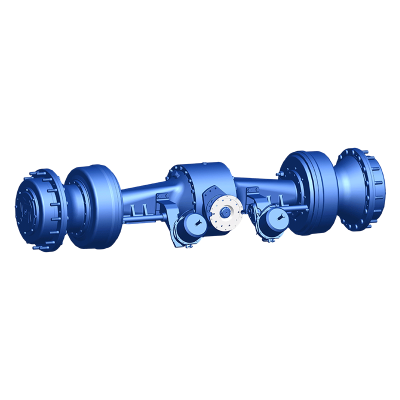

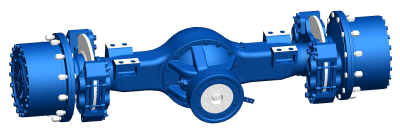

The first batch of modular leading bridges of the steering, specially designed for loading telescopic forks by the company Shandong Lutong Heavy Industry Machinery Co., Ltd., successfully delivered to well -known domestic manufacturers. The production of this batch of products will not only mark a large breakthrough in the production of new products, but also It demonstrates the ability of the modular production system to rapid response. This series of leading bridges that combine innovative technologies will soon be equipped with the latest generation of intellectual fork loaders that provide powerful energy support in logistics, storage, construction and other areas.

The intellectual system of steering: rethinking the mobility of equipment

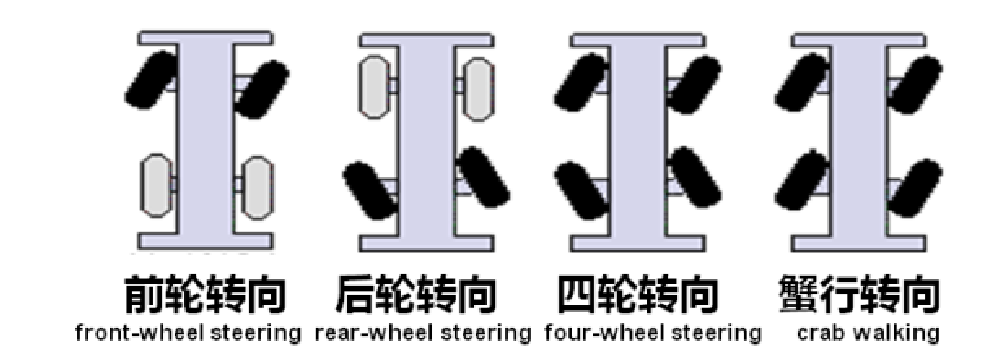

The supply of a leading bridge for loading with telescopic forks is the latest achievement of technological innovations in the industry. Considering the extremely high requirements for telescopic forks for the overall performance of the leading bridge, this product overcame the limitations of the traditional design and ensured a significant increase in performance. After the installation on the main unit, it can support three walking modes: front wheel control, four control, management of the four wheels and crab movement. This innovative design significantly increases the mobility and flexibility of operation of equipment in narrow places.

In the process of real work, the operator can choose the most suitable control method depending on the operating conditions. When moving between warehouse racks, you can use the front wheel control mode to ensure the stability of movement in a straight line; When working on construction sites with a limited space, the four -wheel control mode can significantly reduce the turning radius; And in special conditions of work requiring inclined movement, the Wheel crab mode can demonstrate its unique value. "The flexible switching of these three modes has reduced the number of equipment adjustments by more than 40%, and the efficiency of operation has increased significantly.

Wet braking technology: provides maximum safety

As for the brake system, the leading bridges of this series have an innovative design of normally closed wet braking. The front and rear axes are equipped with completely closed brake systems for complete isolation from dust, dirt and other pollutants. The design of the design is especially well working in conditions of increased dusting, such as mines and construction sites, which significantly reduces the risk of braking refusal caused environmental pollution.

It is worth noting that the efficiency of the thermoregulation of the brake system of the leading bridge with a telescopic fork is excellent. Fores of the test show that the heat from friction released during braking can be quickly absorbed by oil and dissipated through the case, which avoids the “thermal decline”, which is characteristic of dry brake systems. As the same load, the maximum temperature of the wet brake axis is. 150-200 ° C is lower than in the dry braking system, which ensures the stability of braking for a long time.

From the point of view of economic benefit, although the initial cost of acquiring a wet brake system is approximately 30%higher than that of dry maintenance, the cycle of its maintenance is significantly extended, the frequency of replacement of friction materials is reduced by more than 60%, and the cost of the entire life cycle is reduced by 25%-40%. The integrated functions of the front axis form an integrated driving system and the integrated system Parking, which not only optimizes the layout of space, but also reduces the complexity of the system and requirements for maintenance.

Differential speed regulation system: tools for working in difficult conditions

In order to cope with various difficult road conditions, the steering axes of this series are equipped with an improved differential of increased friction and a differential compulsory blocking system. On dirty or loose roads, the differential of increased friction can effectively suppress one -way slippage of the wheels and maintain traction with the road; In extremely severe operating conditions, a compulsory differential lock can provide a rigid wheel connection and efficient power transmission to each wheel.

In the reviews of the tests, one of the customers noted: “On the shaft of the mine, this differential control system has demonstrated excellent performance. Even on dirty slopes, the equipment can maintain stable clutch with the road, which significantly improves the cross -country ability and operational characteristics of the entire machine.” This technical advantage allows the fork loaders, equipped with the leading bridge, adapt to various difficult working conditions - from various difficult work. storage and logistics before the construction of mines.

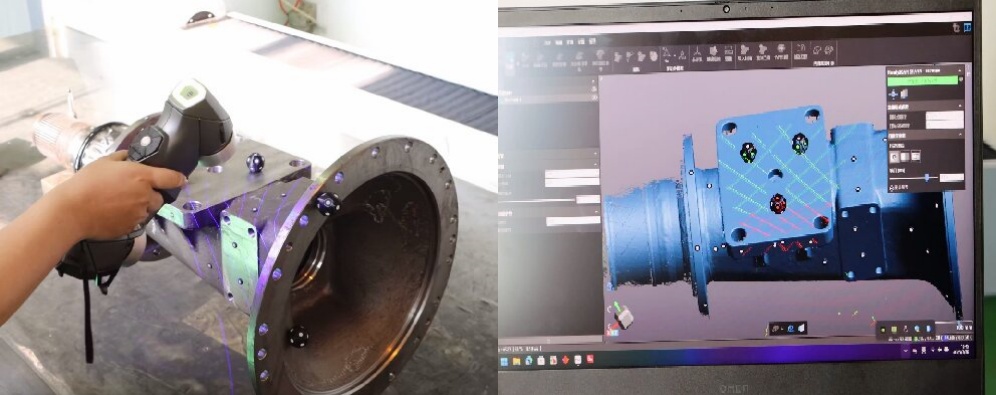

Modular design: quick response to customer needs

This time, a modular design was used in the delivered leading bridge, which provides quick adjustment in accordance with the needs of the customer. To ensure timely deliveries, the company has in advance of the lean production system with sufficient reserves of raw materials and the efficient work of the production line. The quality of the quality of the quality of the quality of the quality of the raw materials to the storage of raw materials to the supply of finished products, in each link there is Strict quality control points. We must ensure not only delivery speed, but also that each product that comes out of the plant meets the highest quality standards.

Customer recognition: Use force to gain market trust

After the first batch of products was delivered, it was immediately highly praised by customers. The customer said, "Lutong Heavy Industry's quick response ability and product quality have exceeded our expectations. The timely delivery of this batch of drive axles ensures the smooth execution of our entire production plan."

The technical support team is fully trained and will provide customers with a full range of technical support. Including installation guidance, commissioning services and follow-up maintenance training. The perfect service system can fully meet customers' needs for training, service and spare parts.

Looking to the Future: Continuous Innovation to Drive Industry Growth

This successful delivery is only the starting point. The company’s work is started to develop new generation products, focusing on electrification and intellectualization. We will continue to deepen the concept of modular design and develop more products that meet the needs of the market. It is expected that with the commissioning of these leading bridges more and more leading manufacturers will be introduced by this innovative innovation Technology. At present, we have received requests from a number of manufacturers and are actively developing plans for subsequent serial production. In the future, the company will develop more leading bridges for loading telescopic forks to improve the range of products.

Shandong Lutong Heavy Industry Machinery Co., Ltd. Always insisted on technological innovations to create value for customers. The successful supply of this leading steering bridge once again confirms the high level of research and development of the company and the level of production in the field of leading bridges. In the future, the company will continue to adhere to the concept “Quality above all, the client is above all” to provide the industry with higher -quality products and technical solutions.