Shandong Lutong Innovates Forestry Machine Drive Axle, Changing the Reliability Standards of Forestry Machinery with Latest Technology

Shandong Lutong has introduced an innovative drive bridge of a logging unit by changing the reliability standards of logging equipment using the latest technologies

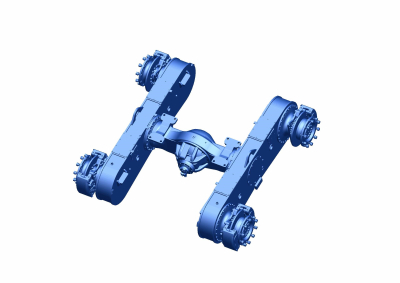

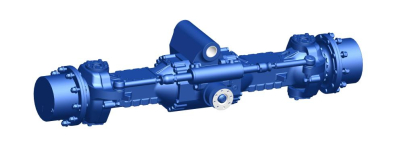

(Shandong, China) July 10, 2025 - in the field of forestry and heavy off -road equipment, the characteristics of the leading bridge directly determine the durability and efficiency of the equipment. Having been the manufacturer of leading bridges in the industry, the company SHANDONG LUTONG independently developed a special leading bridge for the LISTPENSIONAL AND LTP75, which provides comprehensive solutions to work in high intensity conditions due to the use of the most modern materials and precision technologies.

Main advantages: High standards for full connection from components to assembly

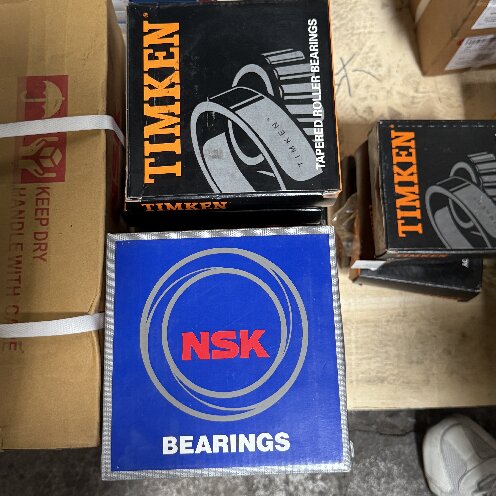

Guaranteeing the operational life of international -level bearings :

The key bearings are imported from Europe with high-load brands, with the impact increased by 30%. They still maintain low friction and high sheri precision under emergency working conditions, which greatly reduces the frequency of equipment maintenance.

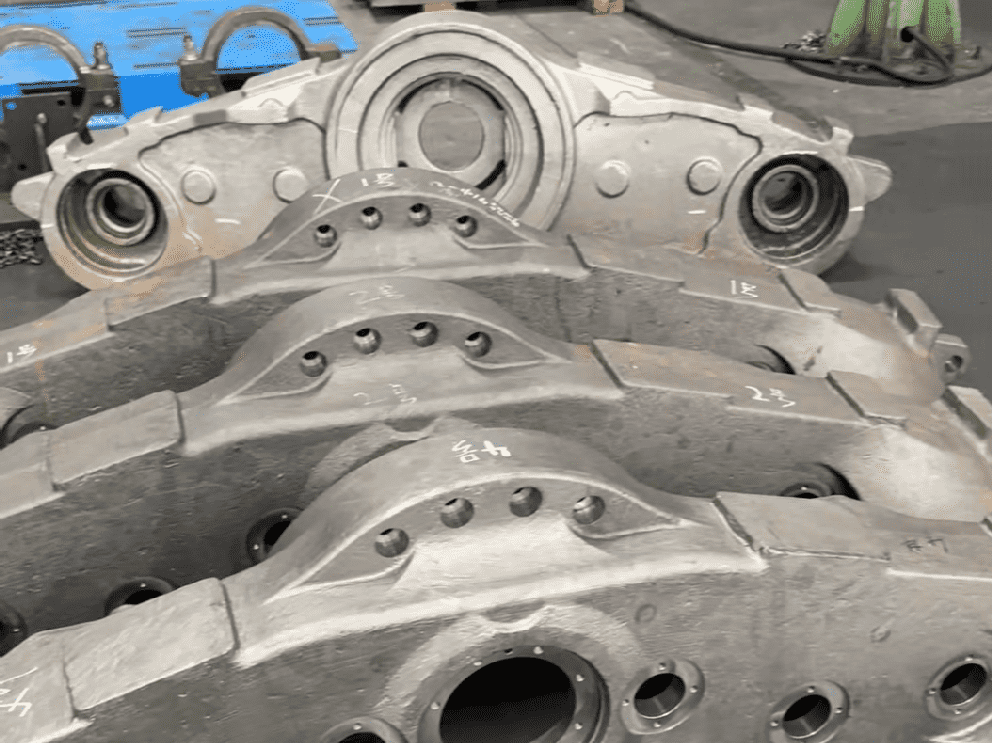

Forged shaft tube + floating oil seal: double compression resistance line:

The shaft tube adopts multi-directional forging process, and the internal metal fibers are continuously dense, which increases the strength by 50% compared with ordinary castings;

The floating oil seal is designed to cope with environments and high humidity, with a seal life exceeding 8,000 hours to eliminate the risk of oil seepage.

High shell and precise processing:

The box is made of high-strength high-quality fox shell, and the five-axis CNC centers ensure the transmission mesh surface tolerance is ≤0.02mm. Combined with the exquisite torque assembly process, the vibration noise is reduced to the industry-leading level.

Strict testing system:

Numerous cavities are subjected to full range seal testing and continuous cycling tests are simulated in temperature differences between -40 to 80℃ to achieve the factory standard of 100% zero leakage.

Real-time display of key components

Semi-axial and planetary wheel axles |

|

Differential cross shaft |

|

Brake chamber body |

Shandong Lutong CTO said, "This product has been focused on the 'barbaric working conditions' of forest machinery since the design stage. We have used parameters higher than the national standard for destructive testing, such as 72-hour full load logging simulation, and the results have shown that its reliability has greatly exceeded customer expectations."

At present, the drive axle has been jointly recognized by forestry manufacturers in many countries such as Russia and Southeast Asia, and will soon be delivered in batches. Shandong Lutong will continue to promote the upgrading of the main components of heavy machinery with the concept of "zero compromise on materials and zero defects in the process."