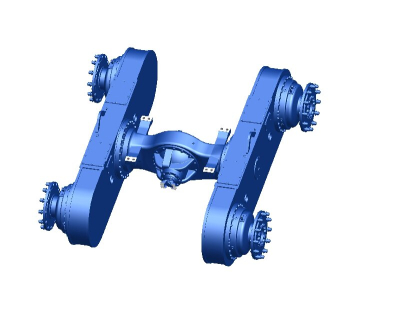

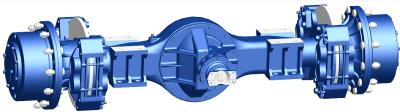

Shandong Lutong WZL150 Steering Drive Axle Limit Test Results Announced: Durability Far Exceeds Industry Standards, Key Data Revealed

Shandong, China - Shandong Lutong today officially published detailed data of the stand tests of the steering bridge of its WZL150 wheeled excavator. After a thorough test in national laboratories, the product has proven itself well in the main indicators, such as fatigue strength, the rigidity of the bearing and gears of the body strength, and some of its indicators, and some of its indicators They even reached the level of mining equipment, which provides a more reliable choice for high-intensity operating rooms of the Russian market.

🔍 Warmed test analysis: going beyond the scope of generally accepted ideas about the industry

1. Testing of the bridge body for fatigue with vertical bending (Syanyang-da Safety Inspection Center)

After 1.146 million cycles, only the screws broke: the main design of the bridge body remained intact, which is much exceeding the requirements of the industrial standard (usually 300,000-500,000 cycles are required).

The deformation value at full load is 1.14 mm/m: under maximum axial load conditions, the deformation value is still controlled within safe limits, which confirms its stability under high load conditions (for example, during excavation work in the permafrost zone in Russia).

2. Gear durability test (China Institute of Automotive Engineering)

2 million cycles of front axle failure-free operation: much higher than other similar wheeled excavator drive axles, equivalent to more than 10 years of intensive use without major repairs.

The rear axle has been damaged 1.9 million times: although this figure is slightly lower than the front axle, it is still much higher than similar products (typically 800,000 to 1.2 million times), and the cause of the damage is the replaceable gearbox, and the maintenance costs are low.

|

|

|

|

🏆The main advantages of the Russian market

✅Long service life: The service life of the equipment is 2 times longer than that of domestic products, which reduces the total cost of ownership for users.

✅Strengthening at extreme temperatures: No brittleness of the bridge shell when impact tested at low temperatures at -45℃ (currently being certified according to the Russian GOST standard).

✅Ease of maintenance: Modular design reduces rear axle gearbox replacement time to 4 hours

📉Industry Data Comparison (Wheel Excavator Drive Axle)

Performance indicators |

Measured data WZL150 |

Main European brands |

Russian products |

Fatigue life of the bridge body |

114.6 Ten thousand times* |

600,000~800,000 times |

400,000~500,000 times |

Robust front axle transmission |

2 million times |

900,000~1.5 million times |

700,000~1 million times |

Full load deformation control |

1.14 mm/m |

1.2~1.5 mm/m |

1.8~2.0 mm/m |

(*Note: As long as a certain number of screws are not broken, the jumper housing will not fail)

🚜Typical application scenarios

Construction of a pipeline in the permafrost zone in Siberia

Loading ore in the Ural mining region

Logging and transportation in the Far East