How drive axle technology innovations are changing the performance standards of modern articulated tractors

The importance and level of development of drive axle technology

As the core component of an articulated tractor's drive axle, the characteristics of an articulated tractor directly determine the performance and reliability of the entire machine. An excellent tractor drive axle system must not only efficiently transmit power but also possess good load capacity, reliability, and adaptability.

From a technical point of view, the leading bridge of the joint tractor must comply with the following basic requirements: the first is to have sufficient strength and rigidity in order to withstand various loads during operation; The second is to have high transmission efficiency and reduce power losses; Third, have good sealing properties that allow you to withstand various loads during operation. prevent leakage of lubricating oil and penetration of external contaminants; The fourth is to have a reasonable mechanism of differential speeds, providing the proper distribution of power between wheels in various road conditions.

Jilled tractors: Energy Revolution and Technological Innovation in Modern Agriculture

Since the mid-20th century, the development of agricultural machinery has undergone radical changes. In 1949, when Elmer Wagner first proposed the concept of an all-wheel drive artist, he probably did not expect that this innovation would completely change the appearance of modern agriculture. After more than 70-year technological development and innovation, the articulated tractors became irreplaceable basic equipment in modern agricultural production. Their unique articulated design and powerful operational capabilities continue to contribute to the transformation and modernization of agricultural production methods, ensuring a reliable guarantee of global food security.

The history of the development of articulated tractors

The history of the development of agricultural technology can be described as the embodiment of the progress of human civilization. Inhibitory with the emergence of agriculture by humans and ending with the use of drain animals and mechanical energy, each technological breakthrough has significantly increased the efficiency of agricultural production. Studies by the main means of mechanization of agriculture, tractors have a particularly outstanding history of development.

The first tractors had a hard design of the frame. Despite the fact that they provided the main capacity, they had obvious shortcomings in mobility and adaptability. Tractic tractors often turn out to be powerless, especially when working on a complex relief and narrow areas. This restriction became more and more obvious in the middle of the 20th century. With the large -scale development of agriculture, the farm area continued to expand, and the requirements for the performance of agricultural machinery became higher and higher.

It was in this context that Elmer Wagner in 1949 proposed an innovative concept of articulated tractors. The main idea of this design is to set the articulated mechanism in the middle of the tractor, due to which the front and rear frames can turn relative to each other, thereby significantly increasing the maneuverability of the entire machine. The irrigation of the artist used the simple mechanical rudder mechanism. Despite the relative simplicity of the design, he has already demonstrated significant advantages.

With the development of hydraulic technologies, the articulated tractors led to important technological breakthroughs. In the 1960s, hydraulic systems began to be widely used in agricultural technology, providing more accurate and reliable steering of articulated tractors. In this period, many well-known agricultural equipment production companies began to invest in research and development to contribute to the rapid development of technology articulated tractors.

After entering the 21st century, with the development of electronic control technologies, the artists have joined the stage of intellectual development. Modern co-articated tractors not only have excellent mechanical properties, but also integrate advanced sensory systems, control systems and information-control systems, which makes them truly intellectual agricultural equipment.

Ttechnical characteristics of innovative products for drive axles

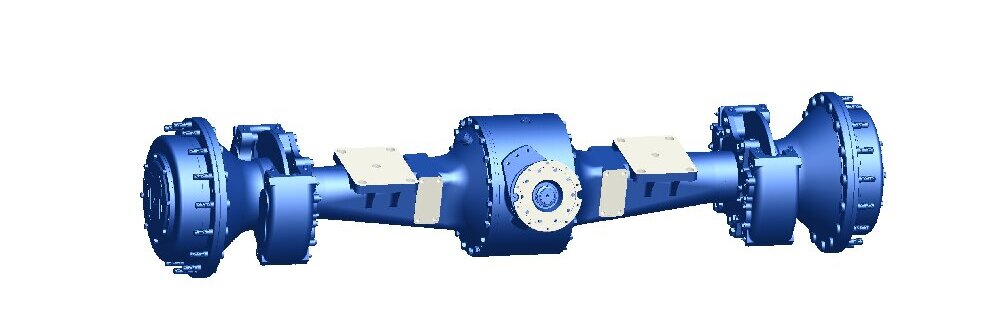

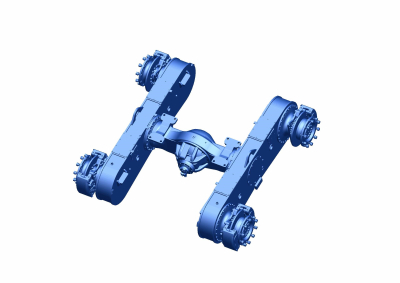

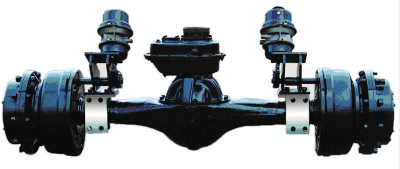

Based on more than 30 years of experience in the field of research and development and production of leading bridges of construction equipment, our company has developed a series of high-performance leading bridges for jointly large power tractors. These products combine our technical developments in the field of material science, mechanical design, production technology, etc. and have excellent operational characteristics and reliability. As for the selection of power, then in our products for leading bridges a modular design is used, which can be adapted to tractors of various power. The segment of 350-430 horsepower segment covers the needs of various difficult operating conditions. In the transmission system, the optimized system is used. A pair of screw gears, and the efficiency of transmission reaches more than 96%, which significantly reduces power loss.

As for constructive design, we use the technology of of the end-element analysis to optimize the design of the bridge shell, providing strength with minimum weight. The material of the bridge case is made of high-strength cast steel, which, after special heat treatment, has excellent rigidity and impact resistance. The patching part of the bearing has an enhanced design that ensures stable accuracy of the support in conditions high load.

As for the sealing systems, we have developed a multi -stage composite compaction system. The spindle is designed with double protrusions, which significantly increases the efficiency of the seal and service life. The end of the end cover has the labyrinth structure in combination with a rubber sealing ring, which effectively prevents the penetration of dirt and water. The ventilation system is performed in the ventilation. waterproof performance, which ensures the normal operation of the leading bridge in marshy conditions.

Our products for leading bridges also have an intellectual update interface, which allows you to easily install temperature, oil, vibration levels and other monitoring devices, providing a hardware basis for predicted maintenance and intellectual control in the future.

Practical application examples and user reviews

Our drive axles are widely used in many countries and regions around the world, especially in areas with harsh agricultural conditions, demonstrating excellent performance and reliability.

In Siberia, Russia, a large agricultural enterprise uses the articulated tractor equipped with our leading bridge. Climatic conditions in this area are severe, in winter the temperature can reach -40 ℃, and in the spring, after the snow gathering, there are slushs on the fields. It is considerable for the reviews of the head of the agricultural equipment department, these tractors have good launch characteristics in Extremely cold conditions, and the fluidity of the lubricant for the leading bridge at low temperatures fully complies with the requirements. During the period of spring sowing, the time of continuous operation of the tractor was more than 18 hours a day, and the leading bridge did not fail.

In the north-east of China, a number of large state farms use articulated tractors equipped with our leading bridges. These farms have a large area of operation, compressed service life and extremely high requirements for the reliability of equipment. The specialist responsible for agricultural equipment said that these leading bridges are fully consistent with the requirements of intensive work and have a service life of more than 10,000 hours, which significantly exceeds expectations. Technical service is also very simple, you only need to regularly check the oil level and replace the lubricant every day.

These examples of practical application fully prove the reliability and adaptability of our products for leading bridges. Dispensers, as a rule, note that our leading bridges have the following advantages: firstly, high reliability and low refusal frequency; Secondly, the simplicity of maintenance and a long service cycle; thirdly, good adaptability and the ability to cope with various difficult working conditions; Fourth, long service life and high payback of investments.

The main reason for the choice of our leading bridge

After more than 30 years of technical improvement and market verification, our drive axle products have won the trust of many customers at home and abroad. By choosing our drive axle products, you will benefit from the following:

Firstly, this is excellent product reliability. Our drive axles have undergone strict quality control, testing and verification to ensure that each product meets design standards.

The second is an impeccable technical service. We have created a professional maintenance team to provide customers with a full range of technical support. It can provide timely and professional services from training the product to installation and commissioning to maintenance. A rich range of products. We offer a wide range of leading bridges of various technical characteristics with a capacity of 350-430 horsepower, which can satisfy the needs of various customers. The fourth is an excellent value for price and quality. We effectively control the production costs of large -scale production and lean control, while ensuring the quality of the products. Products are competitive to our products competitively, competitive to our products. The market, while we provide a longer warranty period and better maintenance, which increases the value of our products for customers.

We believe that thanks to the excellent operational characteristics of our products and the perfect service system, our leading bridges will become an ideal choice for the development of your business in the field of agricultural equipment. We will continue to adhere to the concept of “technological innovation and quality above all” and provide customers around the world with better products and services.